Electrical fires can build from installations or equipment that appear perfectly functional — wiring, panels, appliances that have served years. What makes them particularly dangerous is that they often give little visible warning before ignition: overheating, arcing, or a failed connection inside a panel may go unnoticed until a fire starts.

Especially in industrial settings, the combination of high electrical loads, complex equipment, and heavy duty service means that one fault can escalate quickly to property damage, downtime or injury.

Common locations in industrial sites

Typical high-risk zones include:

- Main or sub-distribution electrical panels (PCCs, MCCs, PLC cabinets)

- Transformer rooms or substations

- Cable trays, vertical shafts and cable vaults

- Motors, variable speed drives, soft-starters and other large electrical equipment

These are areas where energy is high, access may be limited, and faults may evolve behind closed doors.

Root causes

Overloaded systems or circuits

Electrical panels and circuits are designed with a specific load in mind. If extra equipment is added without re-analysing the load or recalibrating protection devices, overheating may result. Overload protection may fail or be bypassed, leading to fire risk.

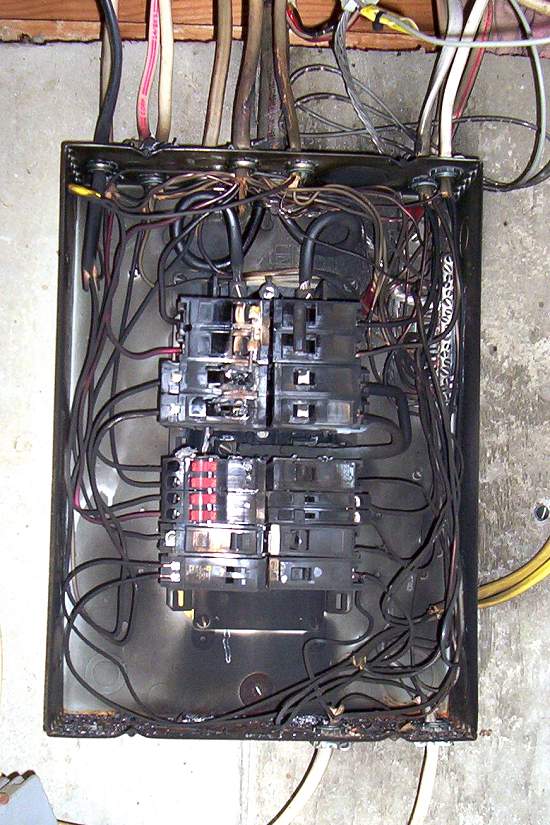

Poorly maintained or outdated equipment

Damaged wiring (frayed, kinked, oxidised), dusty or corroded connections, and aged equipment are common ignition sources. In dusty industrial plants, dust deposits on terminals or busbars increase the chance of tracking, arcing and ultimately fire.

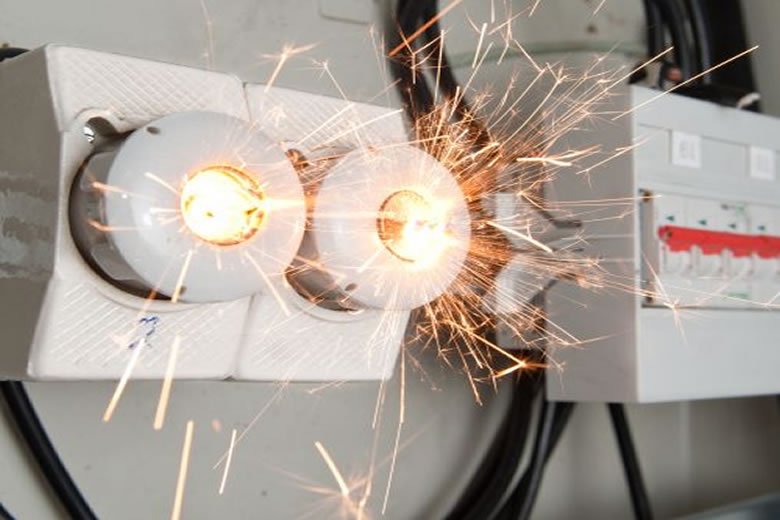

Arc flashes / arcing faults

High-energy events caused by sudden arcing between conductors: triggers can include vibration loosening contacts, dust build up, dropped tools during work inside an enclosure, or defective switchgear. These events can injure personnel, damage equipment catastrophically and start secondary fires.

Warning signals (don’t ignore these)

If you observe any of the following, immediate action is required:

- Electrical panel, motor-drive or equipment casing that is noticeably hot

- Burning or ozone-type smell nearby electrical installations

- Repeated tripping of circuit breakers or blown fuses without obvious cause

- Unexplained power interruptions or sudden changes in electrical behaviour

- Motors or drives performing sluggishly or under heavier load than normal

When such signs appear, isolate or stop the affected equipment (if safe to do so) and call a qualified electrician or maintenance specialist.

What to do when an industrial electrical fire starts

- Sound the alarm and evacuate personnel as per your facility’s emergency plan.

- Notify the fire brigade and/or internal emergency response team (ERT).

- Isolate the power to the installation — only by authorised, trained personnel.

- Follow your local/site fire protection procedures and any relevant building/site regulations.

- If a fixed fire-suppression system is installed, allow it to operate: fixed systems are designed to act sooner than manual response, and in electrical installations often use alternatives to water (which may be inappropriate with live equipment).

Protecting electrical cabinets

Electrical cabinets pose a distinct hazard. Two common protection strategies:

- Direct/local application system: a fire-suppression unit mounted inside the cabinet, detecting and discharging within the cabinet itself.

- Total-flood room system: the entire room (with multiple cabinets) is protected by a system that floods the space with extinguishing agent when fire is detected.

Automatic activation is a major advantage — the system acts quickly and often before a human even opens the panel.

Transformer rooms

Transformers (especially oil-filled types) are hazardous because they combine electrical energy with a combustible medium (the oil). A fire can originate in the transformer and rapidly spread to neighbouring equipment or cables. Rapid suppression by a fixed system (mounted on the transformer or room-wide) plus fire-resisting construction (walls, doors) is key to limiting damage and spread.

Cable trays, shafts and vaults

Cable installations often run through trays, vertical shafts or vaults. When fire starts in such spaces it can propagate quickly via the cables. Conventional sprinklers may not access those enclosed spaces effectively, so special-hazard fixed fire-suppression systems (non-water based or specially designed) are strongly advised for these areas.

In sum, managing industrial electrical fire risk is not just about reacting when fire starts — it’s about designing, installing, maintaining and monitoring electrical systems and fire-protection systems with foresight.

Regular inspection, thermal imaging, clean and tight electrical connections, correct circuit design, up-to-date equipment and speedy response to warning signs are the bedrock of prevention. Coupled with well-engineered fixed suppression systems, the risk of catastrophic loss can be significantly reduced.

For facilities across Europe, ensure your electrical installations adhere to the harmonised standards (such as the IEC/EN 60364 series) and that your fire-suppression systems conform to the relevant EN standards (for example the EN 15276 series for condensed-aerosol systems). Even when the hazard is electrical, fire protection is only as good as the weakest link — whether it’s the wiring, the panel door, the connection torque, or the maintenance schedule.

Stay vigilant, stay compliant — because when the worst happens, being prepared is your best defence.

Sources

- IEC 60364 series “Low-voltage electrical installations” (applicable to industrial, commercial, residential installations) electrical.theiet.org+3Wikipedia+3webstore.iec.ch+3

- “Fixed firefighting systems – Condensed aerosol extinguishing systems – Part 1: Requirements and test methods for components” (EN 15276-1:2019) cdn.standards.iteh.ai+2evs.ee+2

- “Fixed firefighting systems – Condensed aerosol extinguishing systems – Part 2: Design, installation and maintenance” (EN 15276-2:2019) iTeh Standards+2normsplash.com+2

- CENELEC / HD 60364 series for Europe (low voltage electrical installations) Eaton

- Overview of how aerosol suppression systems must meet EN 15276 standards Salgrom+1

- Allianz Risk Consulting Tech Talk on condensed-aerosol fire extinguishing systems (industrial application, advantages/limitations) Allianz Commercial