In hazardous industrial environments, ensuring a continuous supply of breathable air is vital to worker safety. The Automatic Switch-Over Valve (ASV) is a critical safety component used with Self-Contained Breathing Apparatus (SCBA) and Supplied-Air Respirators (SAR), providing automatic transfer of air supply from the primary external airline to the SCBA cylinder in the event of airline pressure loss. This article explains how ASVs operate, outlines their connection and use, reviews the relevant European standards (EN), and discusses safety practices and limitations for their correct deployment.

Workers operating in confined spaces, chemical plants, refineries, offshore platforms, or any environment deemed Immediately Dangerous to Life or Health (IDLH) must rely on dependable respiratory protective equipment (RPE).

Supplied-air respirators (SARs) provide an extended air supply through an external airline, but if that supply is interrupted, the user may be at immediate risk.

To eliminate this hazard, many systems integrate an Automatic Switch-Over Valve (ASV) that seamlessly transfers the air source from the external airline to the SCBA cylinder. This ensures uninterrupted breathing air while the wearer evacuates the hazardous area safely.

The ASV thus enables combined use of two certified respiratory systems:

- Airline apparatus (EN 14593) > the primary air source.

- SCBA (EN 137) > the emergency backup and escape source.

System Configuration and Operation

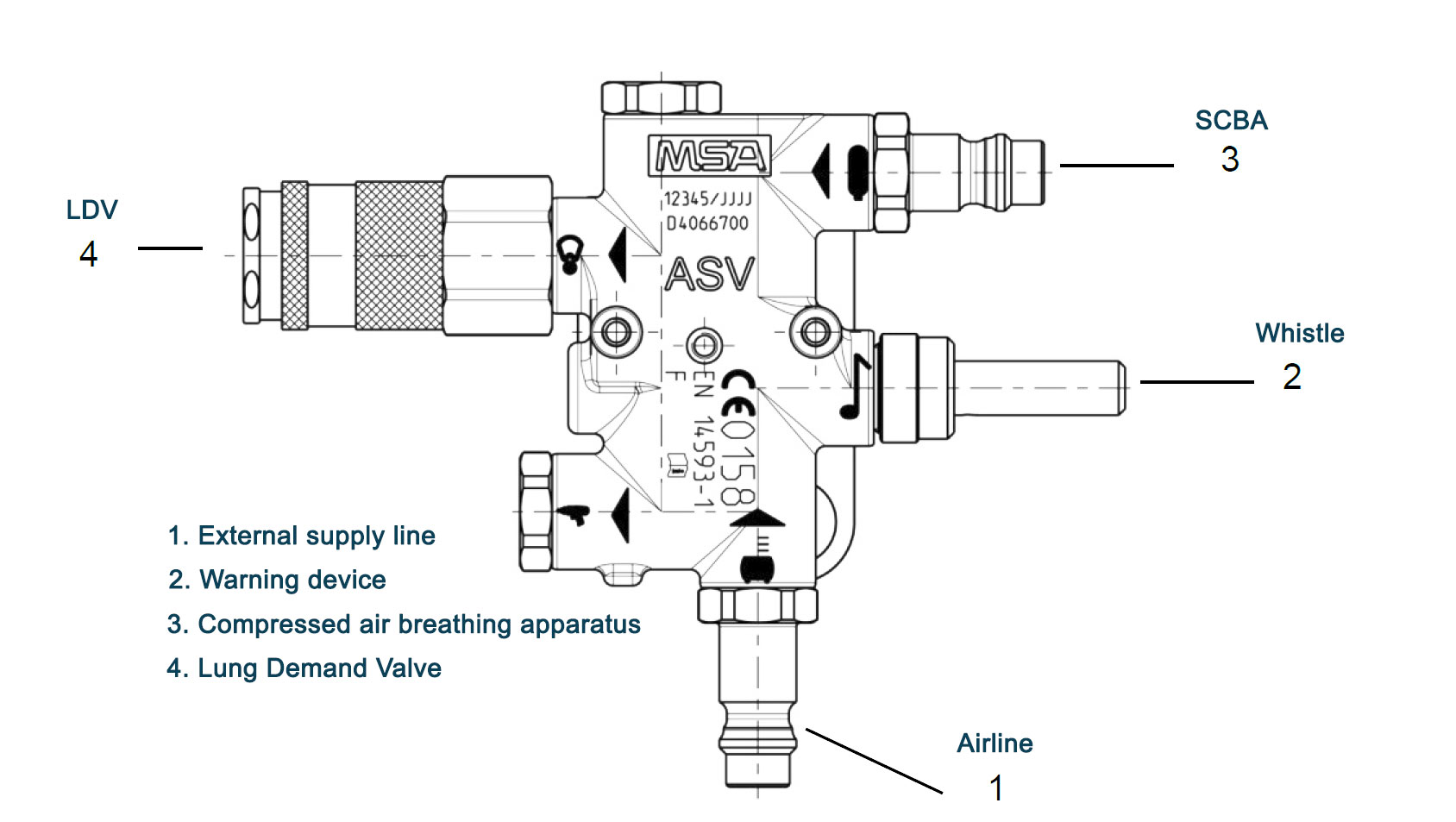

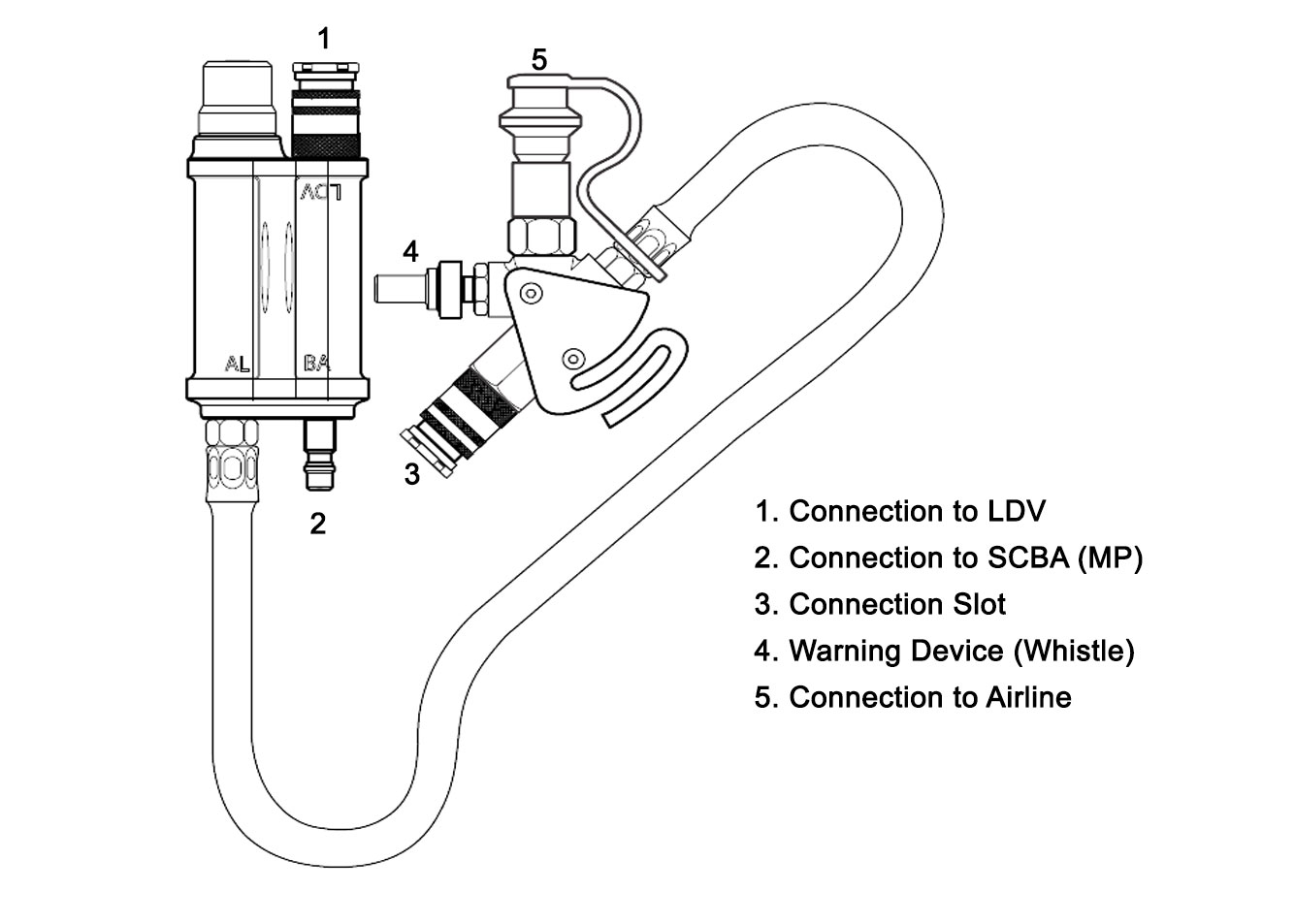

Connections

The ASV is typically mounted at the wearer’s waist and links three air pathways:

| Connection | Function |

| Input 1 – Airline Supply | Connects to the external air source (compressor or cascade system). |

| Input 2 – SCBA Medium Pressure | Connects to the SCBA’s medium-pressure outlet from the first-stage reducer. |

| Output – To Demand Valve | Feeds the lung-governed demand valve (LGDV or LDV) on the full-face mask. |

Correct assembly and leak-free connections are essential for safe operation.

Operational Flow

- Preparation and Pressurization : Don the SCBA and mask, open the SCBA cylinder valve fully, and confirm a positive pressure seal.

- Connect to Airline : Attach the external supply hose to the ASV’s airline input. Working pressure is generally between 6 bar and 10 bar, depending on manufacturer specifications.

- Normal Use : When airline pressure is above the switch-over threshold (typically 4.5–5.3 bar), the ASV supplies air from the external source while keeping the SCBA cylinder in reserve.

- Automatic Switch-Over : If airline pressure falls below the preset level, the ASV instantly switches to the SCBA cylinder supply.

- Warning Signal : An audible alarm activates to alert the wearer that they are now breathing from a finite supply and must exit the hazardous zone immediately.

Some ASVs automatically revert to airline air when pressure is restored, while others require manual reset.

Legislative and Standards Framework

The design, performance, and use of ASVs are governed under several harmonised European Norm (EN) standards for respiratory protective devices:

| EN Standard | Title and Scope |

| EN 14593-1 / -2 | Compressed-air line breathing apparatus with a demand valve. Defines requirements for the primary airline system. |

| EN 137:2006 (Type 2) | Self-contained open-circuit compressed-air breathing apparatus with full face mask. Covers the backup SCBA system, particularly for high-stress or fire-fighting applications. |

| EN 12021 | Compressed air for breathing apparatus. Specifies purity and air quality limits for both the airline and SCBA cylinders. |

| EN 136:1998 (or updated version) | Full-face masks. Defines performance and sealing requirements for the mask component. |

Together, these standards ensure all system components are compatible, safe, and capable of maintaining breathable air quality during normal and emergency conditions.

Operational Integrity and Compliance

For combined airline-SCBA systems, manufacturers must verify that their ASVs are tested and approved for use with specific models of SCBA. For example, the Dräger PAS ASV and MSA Automatic Switch Valve are tested to meet both EN 14593 and EN 137 when used with their respective certified apparatus. Users must always consult the manufacturer’s Instructions for Use (IFU) to confirm compatibility, switch-over pressure settings, and maximum airline lengths.

Each ASV undergoes performance testing to ensure instantaneous switch-over under simulated airline pressure loss, as required by EN standards.

Proper maintenance, periodic inspection, and function testing before each use are mandatory to preserve system integrity.

Limitations and Human Factors

While the airline system provides an effectively unlimited air supply, user endurance and physiological strain impose strict limits on wearing time.

Continuous operation is typically restricted to 60 minutes or less, followed by a recovery period, to prevent fatigue, dehydration, and heat stress.

Additional limitations include:

- Finite SCBA supply: The cylinder is for escape only—typically 15–30 minutes of air.

- Equipment weight and heat load: The full apparatus increases cardiovascular strain.

- Reduced visibility and communication: Masks can fog and muffle speech; use of electronic amplifiers is recommended.

- Airline length limits: Usually restricted to ~100 m, depending on hose diameter and manufacturer specifications.

- Air quality assurance: The external air source must meet EN 12021 purity levels and be monitored by a competent breathing-air (BA) controller.

Safety and Best Practices

To ensure user safety, the following best practices are essential:

- Medical Fitness: Only medically cleared personnel should operate ASV-SCBA systems due to the physical demands involved.

- Fit Testing: Perform and document annual facepiece fit tests.

- Buddy System: Never enter a hazardous environment alone; maintain visual or audible contact.

- Pre-Use Checks: Confirm correct ASV function, switch-over activation, and alarm sound prior to entry.

- Cylinder Valve: Keep the SCBA cylinder valve fully open during operation to guarantee instant air flow upon switch-over.

- Training: Conduct frequent drills that simulate airline failure to build automatic escape response.

- Air Quality Monitoring: Regularly test compressed air for contaminants such as CO, oil vapour, and moisture.

- Record Keeping: Log all switch-over events, maintenance actions, and air-quality test results.

Automatic Switch-Over Valves are indispensable safety devices that protect workers from sudden loss of air supply in hazardous atmospheres.

When used in accordance with EN 14593, EN 137, EN 12021, and EN 136, and supported by proper training and maintenance, ASV-equipped systems provide both operational flexibility and life-saving reliability.

Their effectiveness, however, depends on disciplined operational control, verified equipment compatibility, and continuous vigilance in air-quality management. For industrial safety teams, adopting rigorous ASV procedures is not only regulatory compliance; it is a critical step toward safeguarding every worker who depends on breathable air.

| Article by John S. Retsios | |

|

John S. Retsios is a Health & Safety Consultant and personal protective equipment (PPE) trainer with more than 20 years of field experience. He specializes in equipment and response solutions for hazardous materials (HazMat) and CBRNe (Chemical, Biological, Radiological, Nuclear, and Explosive) emergencies, providing comprehensive expertise to organizations and professionals operating in demanding environments. » https://www.linkedin.com |

References

- Dräger. PAS ASV Product Information (PI 9046290 EN-GB).

- MSA Safety. Automatic Switch Valve Technical Data Sheet.

- EN 137:2006 – Self-Contained Open-Circuit Compressed Air Breathing Apparatus.

- EN 14593-1:2018 – Compressed Air Line Breathing Apparatus with Demand Valve.

- EN 12021 – Compressed Air for Breathing Apparatus.

- EN 136:1998 – Full-Face Masks.

- National and company-specific SOPs for IDLH and confined-space work.